For Better Pelletization and Sintering

OB-1205

OB-1205

Organic Binder, OB-1205 replaces Bentonite in Iron Ore Pelletization process. OB-1205 reduces bentonite (reducing SiO2 & Al2O3 impurities) in iron ore pelletization and enhances fired pellet characteristics. Even at lowest treatment rates, it reduces contaminants and boosts efficiency.

Organic binder OB-1205 absorbs iron ore moisture and strengthens pellets.

Cross-linked polymer OB-1205 binds minerals. It absorbs surface water and generate a high-viscosity solution, which increases adhesion and promotes polymeric compound-iron ore mineral interaction by generating hydrogen bond, ionic exchange, and electrostatic attraction with mineral surface.

OB-1205 reduces bentonite (reducing SiO2 & Al2O3 impurities) in iron ore pelletization and enhances burnt pellet characteristics. Even at lowest treatment rates, it reduces contaminants and boosts efficiency.

Working Mechanism

OB-1205 is dosed in the ratio of 50 to 100 gm/ton of Iron ore based on its morphology & moisture content.

Organic Binder functions by generating adhesive and cohesive forces for the agglomeration of iron ore minerals, as depicted in the following figure.

Increased interaction with Fe3+ ions is provided by the high molecular weight and extended cross-linking branching chain. These forces are far greater than those generated by the capillary action principle of bentonite, allowing for more than 30% reduction in bentonite usage.

Its high Molecular weight and high solution viscosity make it simple to establish strong cohesion inside the pellet, and its molecular structure has a significant number of active functional groups that generate strong adhesion with minerals

Dosing Mechanism

OB-1205 is added on iron ore conveyor belt through a hopper feeder mechanism. The feed rate of Organic Binder is controlled by varying the rpm of screw feeder

Dosage OB-1205 is dosed in the ratio of 50 to 100 gm/ton of Iron ore based on its Morphology & Moisture content.

Dosing MechanismScanning Electron Microscope (SEM) Test Results

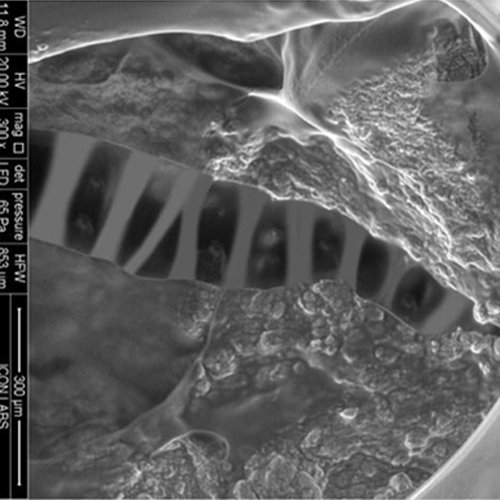

Comparison study under scanning electron microscope of Iron Ore Green Pellet with Bentonite + OB-1205

Comparison study under scanning electron microscope of Iron Ore Green Pellet with Bentonite + OB-1205

Bentonite structure & Bentonite + OB-1205 The gaps are filled by OB-1205 & which are very helpful for iron ore agglomeration. The bentonite and OB-1205 shows effective binding together.

Bentonite structure & Bentonite + OB-1205

The gaps are filled by OB-1205 & which are very helpful for iron ore agglomeration. The bentonite and OB-1205 shows effective binding together.

Due to the strong cohesive and adhesive forces of OB-1205 creates maximum adhesive Bridges

Benefits of OB-1205

- Reduction in Bentonite consumption by (30% - 50%)

- Reduces the generation of fines by improving Tumbling Index

- Reduction of impurities thereby improving operational efficiencies

- Improved quality of finished pellets

- Reduction in cracks formation

- Reduce the specific fuel consumption by 1-3%

- Improved reducibility

- Reduction in Fuel Consumption of blast furnace due to improved quality of product (less slag due to alumina & Silica)

- Lowers handling and logistics cost

- Improves commercial value of the Pellets by increasing Fe content